Development Trends in the Resistor Supply Industry

I. Introduction

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. Their importance cannot be overstated, as they are integral to the operation of virtually all electronic devices, from simple household appliances to complex industrial machinery. The resistor supply industry has evolved significantly over the years, adapting to technological advancements and changing market demands. This article aims to explore the current development trends in the resistor supply industry, shedding light on the factors shaping its future.

II. Historical Context

The history of resistors dates back to the early days of electrical engineering. Initially, resistors were simple wire-wound devices, but as technology progressed, various materials and manufacturing techniques emerged. Key milestones in the resistor supply industry include the introduction of carbon film and metal film resistors, which offered improved performance and reliability. The transition from traditional manufacturing methods to modern techniques, such as automated production and surface mount technology (SMT), has further revolutionized the industry, enabling higher precision and efficiency.

III. Current Market Landscape

A. Overview of the Global Resistor Market

The global resistor market has witnessed substantial growth in recent years, driven by the increasing demand for electronic devices across various sectors. According to market research, the resistor market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 5.2%. Key players in the industry, including Vishay Intertechnology, Yageo Corporation, and Panasonic, hold significant market shares, contributing to the competitive landscape.

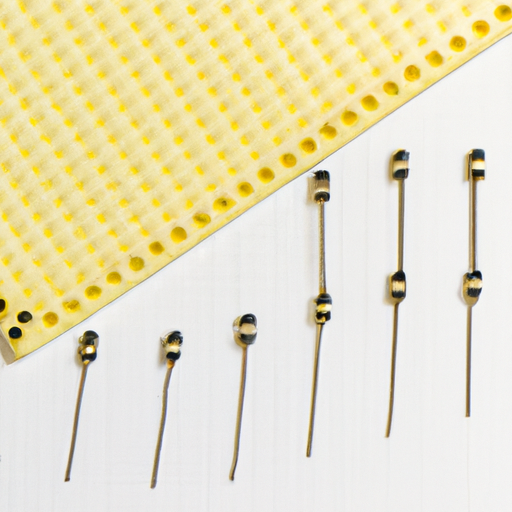

B. Types of Resistors in Demand

The demand for different types of resistors varies based on application requirements. Fixed resistors, which maintain a constant resistance value, are widely used in consumer electronics and automotive applications. Variable resistors, such as potentiometers, are essential for applications requiring adjustable resistance. Specialty resistors, including high-power and precision resistors, are increasingly sought after in industrial automation and telecommunications.

C. Applications Driving Demand

Several applications are driving the demand for resistors. The consumer electronics sector, with its rapid technological advancements, requires reliable and efficient resistors for devices like smartphones, laptops, and home appliances. The automotive industry is also a significant contributor, as modern vehicles incorporate advanced electronic systems that rely on high-performance resistors. Additionally, the industrial automation and telecommunications sectors are expanding, further fueling the need for diverse resistor types.

IV. Technological Advancements

A. Innovations in Resistor Materials

Recent innovations in resistor materials have led to the development of high-precision and high-power resistors. Carbon film and metal film resistors are gaining popularity due to their superior performance characteristics, including low noise and high stability. Wire-wound resistors, known for their robustness, are also being enhanced to meet the demands of high-power applications.

B. Miniaturization and Integration

The trend towards miniaturization in electronics has significantly impacted the resistor supply industry. Surface mount technology (SMT) has become the standard for resistor manufacturing, allowing for smaller, lighter components that can be easily integrated into compact electronic devices. Furthermore, the integration of resistors into semiconductor devices is becoming more common, enabling enhanced functionality and performance.

C. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) has spurred the development of smart resistors equipped with embedded sensors. These advanced resistors can monitor environmental conditions, such as temperature and humidity, and communicate data to connected systems. This innovation is paving the way for smarter devices and applications, enhancing the overall functionality of electronic systems.

V. Sustainability and Environmental Considerations

A. Growing Emphasis on Eco-Friendly Materials

As environmental concerns continue to rise, the resistor supply industry is placing greater emphasis on eco-friendly materials. Manufacturers are exploring alternatives to traditional materials, seeking to reduce their environmental footprint while maintaining performance standards. This shift towards sustainability is becoming a key differentiator in the market.

B. Recycling and Waste Management in Resistor Production

Recycling and waste management practices are gaining traction in the resistor supply industry. Companies are implementing strategies to minimize waste during production and promote the recycling of end-of-life resistors. This not only helps in reducing environmental impact but also aligns with the growing consumer demand for sustainable products.

C. Compliance with Environmental Regulations and Standards

Compliance with environmental regulations and standards is becoming increasingly important for resistor manufacturers. Adhering to guidelines set by organizations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is essential for ensuring that products are safe for consumers and the environment.

VI. Supply Chain Dynamics

A. Impact of Global Supply Chain Disruptions

The COVID-19 pandemic has highlighted vulnerabilities in global supply chains, affecting the resistor supply industry significantly. Disruptions in manufacturing and logistics have led to shortages and delays, prompting companies to reevaluate their supply chain strategies. Geopolitical factors, such as trade tensions and tariffs, have also influenced supply chain dynamics, necessitating a more resilient approach.

B. Strategies for Resilience in the Resistor Supply Chain

To mitigate risks associated with supply chain disruptions, companies are adopting various strategies. Diversification of suppliers is a key approach, allowing manufacturers to reduce dependence on a single source. Additionally, local sourcing and manufacturing are gaining popularity, as companies seek to enhance supply chain resilience and reduce lead times.

VII. Market Trends and Consumer Preferences

A. Shift Towards Customization and Tailored Solutions

As consumer preferences evolve, there is a noticeable shift towards customization and tailored solutions in the resistor supply industry. Customers are increasingly seeking resistors that meet specific performance criteria, prompting manufacturers to offer more flexible options. This trend is particularly evident in industries such as automotive and industrial automation, where unique requirements are common.

B. Increasing Demand for High-Performance Resistors

The demand for high-performance resistors is on the rise, driven by the need for reliability and efficiency in electronic applications. Industries such as telecommunications and automotive are pushing for resistors that can withstand extreme conditions while maintaining accuracy. Manufacturers are responding by developing advanced resistor technologies that meet these stringent requirements.

C. Price Sensitivity and Cost Management Strategies

Despite the growing demand for high-performance resistors, price sensitivity remains a significant factor in the market. Companies are implementing cost management strategies to remain competitive, including optimizing production processes and exploring alternative materials. Balancing performance with cost-effectiveness is crucial for success in the resistor supply industry.

VIII. Future Outlook

A. Predictions for the Resistor Supply Industry

The future of the resistor supply industry looks promising, with continued growth expected in the coming years. As technology advances and new applications emerge, the demand for innovative resistor solutions will likely increase. Manufacturers that prioritize research and development will be well-positioned to capitalize on these opportunities.

B. Emerging Markets and Growth Opportunities

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the resistor supply industry. As these regions experience rapid industrialization and technological adoption, the demand for electronic components, including resistors, is expected to rise. Companies that strategically enter these markets can benefit from increased sales and market share.

C. Potential Challenges and Risks

While the outlook is positive, the resistor supply industry faces potential challenges and risks. Supply chain disruptions, fluctuating raw material prices, and evolving regulatory requirements could impact operations. Companies must remain agile and proactive in addressing these challenges to ensure long-term success.

IX. Conclusion

In summary, the resistor supply industry is undergoing significant transformations driven by technological advancements, market dynamics, and sustainability efforts. Understanding these development trends is crucial for stakeholders looking to navigate the evolving landscape. As the industry continues to adapt to changing consumer preferences and global challenges, staying informed about these trends will be essential for success in the future.

X. References

1. Market Research Reports on Resistor Industry

2. Industry Journals and Publications

3. Company Annual Reports and Press Releases

4. Environmental Regulations and Standards Documentation

5. Interviews with Industry Experts and Analysts

This blog post provides a comprehensive overview of the development trends in the resistor supply industry, highlighting key factors that are shaping its future. By exploring historical context, current market dynamics, technological advancements, and sustainability efforts, readers can gain valuable insights into this essential component of the electronics sector.