What Product Types are Included in Resistor Packaging?

I. Introduction

A. Definition of Resistor Packaging

Resistor packaging refers to the various methods and materials used to encase resistors, which are essential components in electronic circuits. These packages not only protect the resistors from environmental factors but also facilitate their integration into electronic devices. The choice of packaging can significantly influence the performance, reliability, and overall efficiency of electronic systems.

B. Importance of Resistor Packaging in Electronics

In the world of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. The packaging of these resistors is equally important, as it affects their thermal management, electrical performance, and mechanical stability. Proper resistor packaging ensures that these components can withstand the rigors of their operating environments, thereby enhancing the longevity and reliability of electronic devices.

C. Overview of the Article

This article will explore the various product types included in resistor packaging, detailing the different types of resistors, packaging methods, materials used, industry standards, and innovations in the field. By understanding these aspects, readers will gain a comprehensive view of how resistor packaging impacts electronic design and functionality.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors are the most common type of resistors, providing a constant resistance value. They are widely used in various applications, including voltage dividers, current limiters, and pull-up/pull-down configurations.

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption capability and are often used in high-power applications.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise compared to carbon composition resistors, making them suitable for precision applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power supplies and audio equipment.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: These are commonly used for volume control in audio devices and as adjustable voltage dividers in various applications.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications requiring variable resistance, such as in light dimmers.

C. Specialty Resistors

Specialty resistors are designed for specific applications and often have unique characteristics.

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure and are commonly used in light-sensing applications.

3. **Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes, varistors are essential in surge protection devices.

III. Resistor Packaging Types

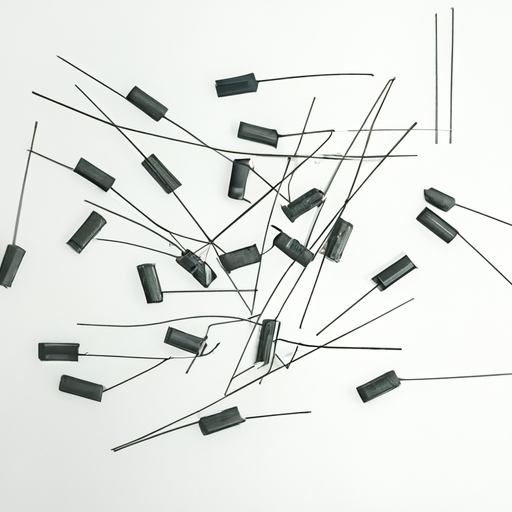

A. Through-Hole Packaging

1. **Description and Characteristics**: Through-hole packaging involves inserting resistor leads through holes in a printed circuit board (PCB) and soldering them in place. This method provides strong mechanical support and is suitable for high-power applications.

2. **Common Applications**: Through-hole resistors are often used in older electronic devices, prototyping, and applications where durability is critical.

B. Surface Mount Technology (SMT) Packaging

1. **Description and Characteristics**: SMT packaging allows resistors to be mounted directly onto the surface of a PCB, eliminating the need for holes. This method enables higher component density and is ideal for automated assembly processes.

2. **Common Applications**: SMT resistors are widely used in modern electronics, including smartphones, computers, and consumer electronics, where space and weight are critical factors.

C. Chip Resistors

1. **Description and Characteristics**: Chip resistors are small, rectangular components that are designed for surface mounting. They offer excellent performance in terms of size, reliability, and thermal management.

2. **Common Applications**: Chip resistors are commonly found in compact electronic devices, such as wearables, IoT devices, and automotive applications.

D. Network Resistors

1. **Description and Characteristics**: Network resistors consist of multiple resistors packaged together in a single component. They simplify circuit design and reduce PCB space.

2. **Common Applications**: These resistors are often used in applications requiring multiple resistive values, such as in analog signal processing and voltage divider networks.

IV. Materials Used in Resistor Packaging

A. Substrate Materials

1. **Ceramic**: Ceramic substrates are commonly used for their excellent thermal stability and electrical insulation properties. They are ideal for high-power and high-frequency applications.

2. **Epoxy**: Epoxy materials are often used in SMT and chip resistors due to their lightweight and durable nature. They provide good protection against moisture and environmental factors.

B. Conductive Materials

1. **Carbon**: Carbon is frequently used in carbon composition and carbon film resistors. It offers good performance at a low cost but may have higher noise levels compared to metal-based resistors.

2. **Metal Alloys**: Metal alloys, such as nickel-chromium, are used in metal film and wirewound resistors. They provide better stability, lower temperature coefficients, and improved performance in precision applications.

C. Protective Coatings

1. **Conformal Coatings**: These coatings protect resistors from moisture, dust, and other environmental factors, enhancing their reliability in harsh conditions.

2. **Encapsulation Materials**: Encapsulation materials provide additional protection for resistors, especially in high-stress environments, ensuring long-term performance and durability.

V. Packaging Standards and Regulations

A. Industry Standards (e.g., IPC, JEDEC)

Various industry standards govern resistor packaging to ensure quality and reliability. Organizations like IPC (Institute for Printed Circuits) and JEDEC (Joint Electron Device Engineering Council) establish guidelines for manufacturing, testing, and performance.

B. Environmental Regulations (e.g., RoHS, REACH)

Environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), dictate the materials used in resistor packaging to minimize environmental impact and ensure safety.

C. Quality Assurance and Testing Protocols

Quality assurance protocols are essential in the resistor manufacturing process. Testing methods, including thermal cycling, humidity testing, and electrical performance evaluations, ensure that resistors meet industry standards and customer expectations.

VI. Innovations in Resistor Packaging

A. Miniaturization Trends

As electronic devices become smaller and more compact, the demand for miniaturized resistors has increased. Innovations in packaging technology have led to the development of smaller, more efficient resistor designs that maintain performance while reducing size.

B. Enhanced Thermal Management Solutions

With the rise of high-power applications, effective thermal management has become crucial. New packaging materials and designs are being developed to improve heat dissipation, ensuring that resistors operate within safe temperature ranges.

C. Smart Resistor Technologies

The integration of smart technologies into resistor packaging is an emerging trend. Smart resistors equipped with sensors and communication capabilities can provide real-time data on performance, enabling predictive maintenance and improved circuit management.

VII. Conclusion

A. Summary of Key Points

Resistor packaging is a vital aspect of electronic design, encompassing various types of resistors, packaging methods, materials, and industry standards. Understanding these elements is essential for engineers and designers to create reliable and efficient electronic systems.

B. Future Trends in Resistor Packaging

As technology continues to evolve, resistor packaging will likely see further innovations, including advancements in miniaturization, thermal management, and smart technologies. These trends will shape the future of electronic design and functionality.

C. Final Thoughts on the Importance of Resistor Packaging in Modern Electronics

In conclusion, resistor packaging plays a critical role in the performance and reliability of electronic devices. By selecting the appropriate packaging methods and materials, engineers can ensure that resistors function optimally, contributing to the overall success of electronic systems.

VIII. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Market Research Reports on Resistor Technologies

- IPC Standards and Guidelines

C. Manufacturer Specifications and Guidelines

- Manufacturer datasheets for various resistor types

- Guidelines from leading resistor manufacturers on packaging and applications

This comprehensive overview of resistor packaging highlights its significance in the electronics industry, providing valuable insights for professionals and enthusiasts alike.