What are the Popular Models of Resistor Standards?

I. Introduction

Resistors are fundamental components in electronic circuits, serving to limit current flow, divide voltages, and dissipate energy. Resistor standards are essential guidelines that ensure the reliability, performance, and compatibility of resistors across various applications. These standards are crucial for manufacturers, engineers, and designers, as they provide a framework for selecting the right resistors for specific tasks. In this article, we will explore the historical context of resistor standards, the different types of resistors, popular resistor standards, factors influencing resistor selection, their applications, and future trends in this vital area of electronics.

II. Historical Context of Resistor Standards

The journey of resistor standards began in the early 20th century when the need for reliable and consistent electronic components became apparent. As technology advanced, the demand for precision and accuracy in electronic devices grew, leading to the establishment of various standards. Key milestones in resistor development include the introduction of carbon composition resistors in the 1920s, which were widely used until the 1960s when metal film and wirewound resistors gained popularity due to their improved performance.

Organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) played pivotal roles in the standardization of resistors. These organizations developed guidelines that manufacturers could follow to ensure their products met specific performance criteria, thus fostering a more reliable electronics industry.

III. Types of Resistor Standards

Resistors can be categorized into several types, each with its own standards and applications.

A. Fixed Resistors

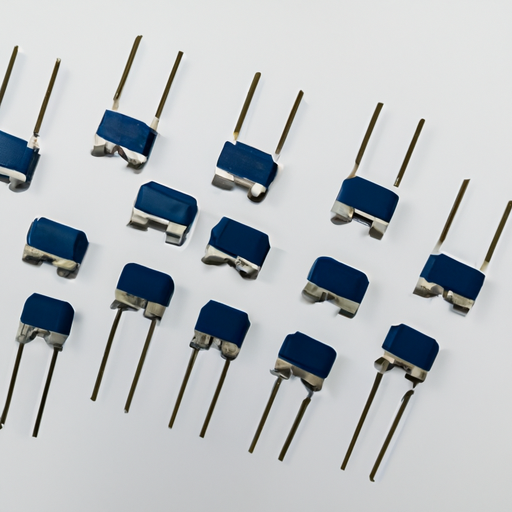

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption and are often used in applications where high pulse power is required. However, they have a higher tolerance and temperature coefficient compared to other types.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability and lower noise than carbon composition resistors, making them suitable for precision applications.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications. They are known for their accuracy and stability.

B. Variable Resistors

1. **Potentiometers**: These are adjustable resistors that allow users to change resistance values manually. They are commonly used in volume controls and other applications where variable resistance is needed.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current. They are typically used in high-power applications and can handle larger currents than standard potentiometers.

C. Specialty Resistors

1. **Precision Resistors**: These resistors are designed for high accuracy and low tolerance, making them ideal for applications in instrumentation and measurement.

2. **Current Sensing Resistors**: Used to measure current flow in a circuit, these resistors are designed to have a low resistance value to minimize power loss while providing accurate readings.

3. **High Voltage Resistors**: These resistors are built to withstand high voltage levels and are used in applications such as power supplies and high-voltage testing equipment.

IV. Popular Resistor Standards

A. E12 and E24 Series

The E-series is a set of preferred numbers that define standard resistor values. The E12 series includes 12 values per decade, while the E24 series includes 24 values. These series are widely used in electronic design and manufacturing, providing a simple way to select resistor values that are readily available.

B. E96 and E192 Series

For applications requiring higher precision, the E96 and E192 series offer 96 and 192 values per decade, respectively. These series are essential in high-accuracy applications, such as precision measurement instruments and high-end audio equipment, where even slight variations in resistance can significantly impact performance.

C. International Electrotechnical Commission (IEC) Standards

The IEC has established various standards for resistors, focusing on performance, safety, and environmental considerations. These standards ensure that resistors manufactured globally meet specific criteria, promoting consistency and reliability in electronic components.

D. American National Standards Institute (ANSI) Standards

ANSI, in collaboration with IEEE, has developed standards that govern resistor performance in the U.S. market. These standards are crucial for manufacturers and engineers, ensuring that products meet the necessary requirements for safety and performance.

V. Factors Influencing Resistor Selection

When selecting resistors, several factors must be considered to ensure optimal performance in a given application.

A. Tolerance and Temperature Coefficient

Tolerance refers to the allowable deviation from the nominal resistance value, while the temperature coefficient indicates how much the resistance changes with temperature. Both factors are critical in applications where precision is essential.

B. Power Rating and Voltage Rating

The power rating indicates the maximum power a resistor can dissipate without overheating, while the voltage rating specifies the maximum voltage that can be applied across the resistor. Selecting resistors with appropriate ratings is vital to prevent failure in electronic circuits.

C. Environmental Considerations

Resistors may be exposed to various environmental conditions, such as humidity, temperature fluctuations, and mechanical stress. Choosing resistors that can withstand these conditions is essential for ensuring long-term reliability.

D. Cost and Availability

Cost and availability are practical considerations when selecting resistors. Engineers must balance performance requirements with budget constraints and the availability of specific resistor types in the market.

VI. Applications of Resistor Standards

Resistor standards play a crucial role in various industries and applications.

A. Consumer Electronics

In consumer electronics, resistors are used in devices such as televisions, smartphones, and computers. Adhering to resistor standards ensures that these devices function reliably and efficiently.

B. Industrial Applications

In industrial settings, resistors are used in control systems, automation, and machinery. Standards help maintain performance and safety in these critical applications.

C. Automotive Industry

The automotive industry relies on resistors for various functions, including sensor applications and electronic control units. Resistor standards ensure that components can withstand the harsh conditions of automotive environments.

D. Telecommunications

In telecommunications, resistors are essential for signal processing and transmission. Standards help ensure that resistors perform consistently, contributing to the reliability of communication systems.

VII. Future Trends in Resistor Standards

As technology continues to evolve, several trends are shaping the future of resistor standards.

A. Advances in Material Science

New materials are being developed to enhance resistor performance, including improved thermal stability and lower noise levels. These advancements will lead to more reliable and efficient resistors.

B. Miniaturization and Integration

The trend toward miniaturization in electronics is driving the development of smaller resistors that can be integrated into compact devices. This trend will require new standards to ensure performance in smaller packages.

C. The Role of Digital Technology

Digital technology is influencing resistor design and manufacturing, with the potential for smart resistors that can provide real-time data on performance and condition.

D. Sustainability and Environmental Impact

As the electronics industry moves toward more sustainable practices, resistor standards will need to address environmental considerations, including the use of eco-friendly materials and manufacturing processes.

VIII. Conclusion

In summary, resistor standards are vital for ensuring the reliability and performance of electronic components across various applications. Understanding the historical context, types of resistors, popular standards, and factors influencing selection is essential for engineers and manufacturers. As technology continues to advance, staying informed about future trends will be crucial for adapting to the evolving landscape of resistor standards. Adhering to these standards not only enhances product quality but also contributes to the overall safety and efficiency of electronic systems.

IX. References

- Academic Journals

- Industry Publications

- Standards Organizations Websites

This comprehensive overview of popular models of resistor standards highlights their significance in the electronics industry and provides valuable insights for professionals involved in design, manufacturing, and application of resistors.