What are the Product Features of Capacitor Compensation?

I. Introduction

In the realm of electrical engineering, capacitor compensation plays a pivotal role in enhancing the efficiency and reliability of electrical systems. Capacitor compensation refers to the use of capacitors to improve power factor, stabilize voltage levels, and mitigate harmonics in electrical networks. As industries and commercial establishments increasingly rely on complex electrical systems, understanding the importance and features of capacitor compensation becomes essential. This article delves into the fundamental principles of capacitor compensation, its key product features, applications, and considerations for implementation.

II. Understanding Capacitor Compensation

A. Basic Principles of Capacitor Compensation

1. **Reactive Power and Power Factor**: In electrical systems, power can be categorized into active power (real power) and reactive power. Active power is the actual power consumed by devices to perform work, while reactive power is necessary for maintaining the electric and magnetic fields in inductive loads, such as motors and transformers. The power factor, a measure of how effectively electrical power is being converted into useful work output, is defined as the ratio of active power to apparent power. A low power factor indicates inefficient use of electrical power, leading to increased energy costs and potential penalties from utility companies.

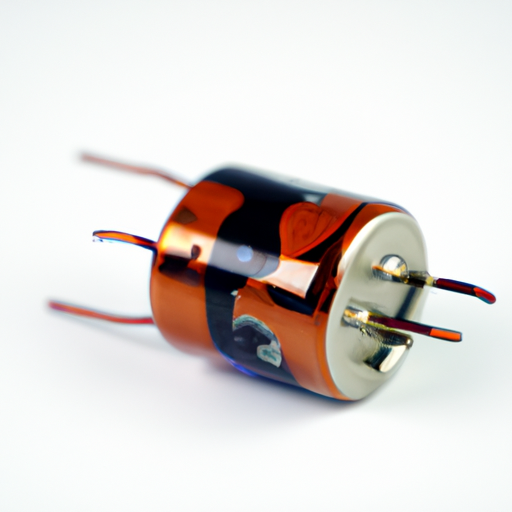

2. **Role of Capacitors in Electrical Systems**: Capacitors are devices that store electrical energy in an electric field. When connected to an electrical system, they can supply reactive power, thereby reducing the overall demand for reactive power from the grid. This not only improves the power factor but also enhances the overall efficiency of the electrical system.

B. Types of Capacitor Compensation

1. **Shunt Capacitors**: These are connected in parallel with the load and are commonly used for power factor correction. By providing reactive power locally, shunt capacitors reduce the amount of reactive power that must be supplied by the utility, thus improving the power factor.

2. **Series Capacitors**: Connected in series with the load, these capacitors are primarily used to increase the voltage across the load. They are often employed in transmission lines to improve voltage stability and reduce losses.

3. **Synchronous Condensers**: These are rotating machines that can provide reactive power support to the grid. They can be adjusted to either absorb or generate reactive power, making them versatile tools for voltage regulation and power factor correction.

III. Key Product Features of Capacitor Compensation

A. Power Factor Correction

1. **Improvement of Power Factor**: One of the primary features of capacitor compensation is its ability to improve the power factor of an electrical system. By supplying reactive power locally, capacitors reduce the need for reactive power from the grid, leading to a higher power factor.

2. **Reduction of Reactive Power Demand**: With improved power factor, the overall demand for reactive power decreases. This not only lowers energy costs but also reduces the strain on the electrical infrastructure.

B. Voltage Regulation

1. **Stabilization of Voltage Levels**: Capacitor compensation helps stabilize voltage levels in electrical systems. By providing reactive power support, capacitors can counteract voltage drops that occur during peak demand periods.

2. **Prevention of Voltage Drops**: Voltage drops can lead to inefficient operation of electrical equipment and potential damage. Capacitor compensation mitigates these drops, ensuring that equipment operates within its specified voltage range.

C. Harmonic Filtering

1. **Mitigation of Harmonics in Electrical Systems**: Harmonics are voltage or current waveforms that deviate from the fundamental frequency, often caused by non-linear loads. Capacitor compensation can help filter out these harmonics, improving the overall power quality.

2. **Enhancement of System Efficiency**: By reducing harmonics, capacitor compensation enhances the efficiency of electrical systems, leading to lower energy losses and improved performance of equipment.

D. Energy Savings

1. **Reduction in Energy Costs**: Improved power factor and reduced reactive power demand translate to lower energy costs for businesses. Many utility companies offer incentives for maintaining a high power factor, further enhancing the financial benefits of capacitor compensation.

2. **Increased System Efficiency**: Capacitor compensation not only reduces energy costs but also increases the overall efficiency of the electrical system. This can lead to significant savings over time, especially in large industrial and commercial applications.

E. Equipment Protection

1. **Reduction of Stress on Electrical Equipment**: By stabilizing voltage levels and improving power factor, capacitor compensation reduces the stress on electrical equipment. This can lead to fewer failures and lower maintenance costs.

2. **Prolonged Equipment Lifespan**: With reduced stress and improved operating conditions, the lifespan of electrical equipment can be significantly extended. This is particularly important in industrial settings where equipment replacement can be costly and disruptive.

IV. Applications of Capacitor Compensation

A. Industrial Applications

1. **Manufacturing Facilities**: In manufacturing environments, large motors and inductive loads are common. Capacitor compensation is essential for improving power factor and ensuring efficient operation of machinery.

2. **Large Motors and Drives**: Capacitor compensation helps manage the reactive power demands of large motors and drives, leading to improved performance and reduced energy costs.

B. Commercial Applications

1. **Office Buildings**: In commercial buildings, capacitor compensation can improve energy efficiency and reduce operating costs. This is particularly important in environments with significant lighting and HVAC loads.

2. **Retail Spaces**: Retail establishments benefit from capacitor compensation by reducing energy costs and improving the reliability of electrical systems, which is crucial for maintaining customer satisfaction.

C. Utility Applications

1. **Transmission and Distribution Systems**: Utilities use capacitor compensation to enhance the stability and efficiency of transmission and distribution networks. This helps reduce losses and improve service reliability.

2. **Renewable Energy Integration**: As renewable energy sources become more prevalent, capacitor compensation plays a vital role in managing the variability of these sources and ensuring grid stability.

V. Considerations for Implementing Capacitor Compensation

A. System Assessment

1. **Load Analysis**: Before implementing capacitor compensation, a thorough load analysis is essential. This involves understanding the types of loads present in the system and their reactive power requirements.

2. **Power Quality Assessment**: Assessing the power quality of the electrical system helps identify issues such as harmonics and voltage fluctuations that capacitor compensation can address.

B. Selection of Capacitor Type

1. **Factors Influencing Selection**: The choice of capacitor type depends on various factors, including the specific application, load characteristics, and system requirements.

2. **Sizing and Configuration**: Proper sizing and configuration of capacitors are crucial for achieving optimal performance. This involves calculating the required capacitance to meet the reactive power demands of the system.

C. Maintenance and Monitoring

1. **Regular Inspections**: Regular inspections of capacitor banks are necessary to ensure they are functioning correctly and to identify any potential issues before they escalate.

2. **Performance Monitoring**: Continuous monitoring of system performance helps assess the effectiveness of capacitor compensation and make necessary adjustments.

VI. Conclusion

In summary, capacitor compensation is a vital component of modern electrical systems, offering numerous benefits such as improved power factor, voltage regulation, harmonic filtering, energy savings, and equipment protection. As industries and commercial establishments continue to evolve, the importance of capacitor compensation will only grow. Future trends may include advancements in capacitor technology, increased integration with renewable energy sources, and enhanced monitoring capabilities. Ultimately, understanding and implementing capacitor compensation is essential for optimizing electrical systems and ensuring their reliability and efficiency in an increasingly energy-conscious world.