Popular Thermal Resistor Product Models

I. Introduction

Thermal resistors, commonly known as thermistors and resistance temperature detectors (RTDs), are essential components in various electronic and industrial applications. These devices are designed to measure temperature by correlating resistance changes with temperature variations. Their importance spans across multiple sectors, including manufacturing, automotive, consumer electronics, and medical devices. This article aims to provide an overview of popular thermal resistor product models, their applications, and key considerations for selecting the right thermal resistor for specific needs.

II. Understanding Thermal Resistors

A. What is a Thermal Resistor?

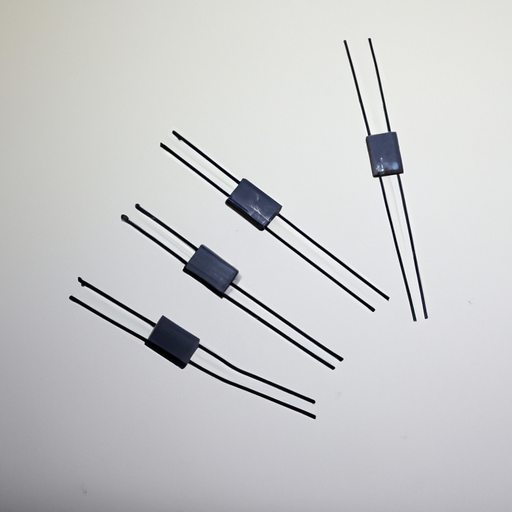

Thermal resistors are temperature-sensitive resistors that change their resistance based on temperature fluctuations. They are primarily used for temperature measurement and control. The two main types of thermal resistors are thermistors and RTDs.

1. Definition and Functionality

Thermistors are made from ceramic materials that exhibit a significant change in resistance with temperature changes. RTDs, on the other hand, are made from pure metals and provide a more linear response over a wider temperature range.

2. Types of Thermal Resistors

Thermistors: These are further classified into Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) thermistors. NTC thermistors decrease in resistance as temperature increases, while PTC thermistors increase in resistance with rising temperature.

RTDs: These devices typically use platinum as the sensing element, providing high accuracy and stability. Common types include PT100 and PT1000, which refer to their resistance at 0°C.

B. How Thermal Resistors Work

1. Principles of Resistance Change with Temperature

The fundamental principle behind thermal resistors is that the resistance of the material changes with temperature. For thermistors, the relationship is often nonlinear, while RTDs exhibit a more linear relationship, making them easier to calibrate for precise measurements.

2. Characteristics of Thermal Resistors

Key characteristics of thermal resistors include their temperature range, accuracy, sensitivity, and response time. These factors are crucial in determining their suitability for specific applications.

III. Key Applications of Thermal Resistors

A. Industrial Applications

Thermal resistors play a vital role in various industrial applications. They are used in manufacturing processes to monitor and control temperatures, ensuring product quality and safety. In HVAC systems, thermal resistors help regulate temperature and maintain comfort levels.

B. Consumer Electronics

In consumer electronics, thermal resistors are used for temperature monitoring in devices such as computers, smartphones, and home appliances. They also serve as safety features, preventing overheating and potential damage.

C. Automotive Industry

The automotive industry relies heavily on thermal resistors for engine temperature monitoring and climate control systems. Accurate temperature readings are essential for optimizing engine performance and ensuring passenger comfort.

D. Medical Devices

In the medical field, thermal resistors are crucial for patient monitoring systems and laboratory equipment. They provide accurate temperature readings, which are vital for patient care and experimental procedures.

IV. Popular Thermal Resistor Product Models

A. Thermistors

1. NTC Thermistors

Model Example: EPCOS B57891M

Key Features and Specifications: This NTC thermistor offers a resistance of 10kΩ at 25°C, with a temperature range of -40°C to +125°C. It is known for its high sensitivity and fast response time, making it ideal for temperature measurement in various applications.

2. PTC Thermistors

Model Example: Vishay 5D-20

Key Features and Specifications: The Vishay 5D-20 PTC thermistor is designed for overcurrent protection and temperature sensing. It has a resistance of 20Ω at 25°C and operates effectively in temperatures ranging from -40°C to +125°C.

B. Resistance Temperature Detectors (RTDs)

1. PT100 RTDs

Model Example: Omega PT100

Key Features and Specifications: The Omega PT100 RTD is a widely used temperature sensor with a resistance of 100Ω at 0°C. It offers high accuracy and stability, making it suitable for industrial applications where precise temperature measurement is critical.

2. PT1000 RTDs

Model Example: Fluke 80PK-8

Key Features and Specifications: The Fluke 80PK-8 PT1000 RTD provides a resistance of 1000Ω at 0°C. It is designed for use in a variety of applications, including HVAC and process control, offering excellent linearity and reliability.

C. Specialty Thermal Resistors

1. High-Temperature Resistors

Model Example: Honeywell 1K3

Key Features and Specifications: The Honeywell 1K3 is a high-temperature thermistor that can operate in extreme conditions, with a temperature range of -40°C to +300°C. It is ideal for applications in harsh environments, such as industrial ovens and furnaces.

2. Low-Temperature Resistors

Model Example: TE Connectivity 100K

Key Features and Specifications: The TE Connectivity 100K thermistor is designed for low-temperature applications, with a resistance of 100kΩ at 25°C. It is commonly used in cryogenic applications and environmental monitoring.

V. Factors to Consider When Choosing Thermal Resistors

When selecting a thermal resistor, several factors should be considered to ensure optimal performance for the intended application:

A. Temperature Range

The temperature range of the thermal resistor should match the operating conditions of the application. Different models are designed for specific temperature ranges, so it is essential to choose one that fits the requirements.

B. Accuracy and Sensitivity

Accuracy is crucial for applications requiring precise temperature measurements. Sensitivity refers to how quickly the thermal resistor responds to temperature changes. Higher sensitivity is often desired in applications where rapid temperature fluctuations occur.

C. Response Time

The response time of a thermal resistor is the time it takes to reach a stable reading after a temperature change. Faster response times are critical in applications where quick temperature monitoring is necessary.

D. Environmental Conditions

Consider the environmental conditions in which the thermal resistor will operate. Factors such as humidity, pressure, and exposure to chemicals can affect the performance and longevity of the device.

E. Cost and Availability

Finally, consider the cost and availability of the thermal resistor. While high-performance models may offer better accuracy and sensitivity, they may also come at a higher price. Balancing performance with budget constraints is essential.

VI. Future Trends in Thermal Resistor Technology

As technology continues to advance, several trends are emerging in the field of thermal resistors:

A. Advancements in Materials

New materials are being developed to enhance the performance of thermal resistors. These materials can improve sensitivity, accuracy, and temperature range, making thermal resistors more versatile for various applications.

B. Integration with IoT and Smart Technologies

The integration of thermal resistors with IoT and smart technologies is becoming increasingly common. This allows for real-time temperature monitoring and data collection, enabling better control and automation in various applications.

C. Miniaturization and Enhanced Performance

Miniaturization is a significant trend in the electronics industry, and thermal resistors are no exception. Smaller, more efficient thermal resistors are being developed to meet the demands of compact electronic devices without compromising performance.

VII. Conclusion

Thermal resistors are vital components in a wide range of applications, from industrial processes to consumer electronics and medical devices. Understanding the different types of thermal resistors, their key features, and popular product models can help in selecting the right device for specific needs. As technology continues to evolve, advancements in materials and integration with smart technologies will further enhance the capabilities of thermal resistors, making them even more indispensable in the future.

VIII. References

- Manufacturer datasheets and product specifications

- Industry publications on thermal resistor technology

- Academic journals on temperature measurement and control systems

This comprehensive overview of popular thermal resistor product models and their applications provides valuable insights for engineers, designers, and anyone interested in temperature measurement technology. By considering the factors outlined in this article, you can make informed decisions when selecting thermal resistors for your projects.