What Components and Modules Does a Chip Adjustable Resistor Contain?

I. Introduction

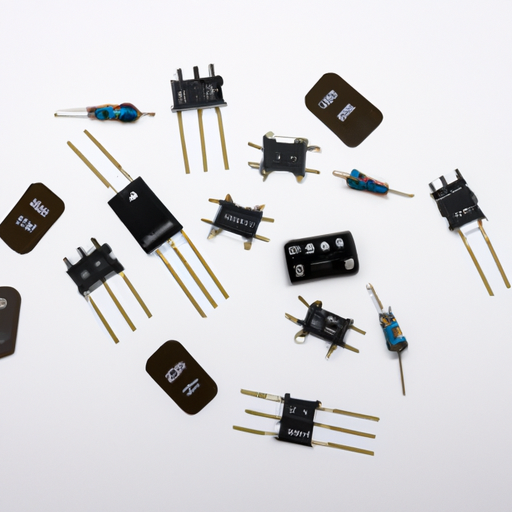

In the realm of electronics, precision and adaptability are paramount. One of the key components that embody these qualities is the chip adjustable resistor. These resistors play a crucial role in various electronic circuits, allowing for fine-tuning of resistance values to meet specific requirements. This article delves into the components and modules that make up chip adjustable resistors, exploring their significance, functionality, and applications in modern electronics.

II. Basic Concepts

A. What is a Resistor?

Resistors are fundamental components in electronic circuits, designed to limit the flow of electric current. They serve various functions, including voltage division, current limiting, and signal attenuation. Resistors come in different types, including fixed and variable resistors, each serving distinct purposes.

B. Understanding Adjustable Resistors

Adjustable resistors, also known as variable resistors, allow users to change their resistance values. This flexibility is essential in applications where precise control over electrical parameters is necessary. Unlike fixed resistors, which have a predetermined resistance value, adjustable resistors can be fine-tuned to achieve desired circuit performance.

III. Components of a Chip Adjustable Resistor

A. Resistive Element

The core of any resistor is its resistive element, which determines its resistance value. In chip adjustable resistors, this element is typically made from materials such as carbon, metal film, or thick film. The choice of material affects the resistor's performance characteristics, including temperature stability and tolerance. The resistance value range can vary widely, allowing for applications in both low and high resistance scenarios.

B. Adjustment Mechanism

The adjustment mechanism is a critical component of chip adjustable resistors, enabling users to modify the resistance value. There are two primary types of adjustment: digital and analog.

1. **Digital Adjustment**: This method utilizes electronic controls, often integrated into microcontrollers or digital signal processors. Users can adjust resistance values through software, providing high precision and repeatability.

2. **Analog Adjustment**: This traditional method involves mechanical components, such as potentiometers or trimmers. Users manually turn a knob or slider to change the resistance value, offering a tactile and straightforward interface.

C. Encapsulation

Encapsulation serves multiple purposes, including protecting the internal components from environmental factors and ensuring reliability. Chip adjustable resistors are typically encapsulated in materials like epoxy or ceramic, which provide durability and resistance to moisture, dust, and temperature fluctuations. This protection is vital for maintaining performance in various operating conditions.

D. Terminals and Connections

The terminals of chip adjustable resistors are crucial for integrating them into electronic circuits. There are two main types of terminals:

1. **Surface Mount**: These terminals are designed for mounting directly onto the surface of printed circuit boards (PCBs). They are compact and suitable for modern, space-constrained designs.

2. **Through-Hole**: This traditional method involves inserting the resistor's leads through holes in the PCB and soldering them in place. While less common in contemporary designs, through-hole resistors are still used in specific applications due to their robustness.

Connection methods, such as soldering and bonding, ensure reliable electrical contact between the resistor and the circuit, which is essential for optimal performance.

IV. Modules in Chip Adjustable Resistors

A. Integrated Circuits (ICs)

Integrated circuits play a significant role in the functionality of chip adjustable resistors. Many modern adjustable resistors incorporate ICs that facilitate digital control and enhance performance. These ICs can manage the adjustment process, providing features like memory for storing resistance settings and interfaces for user interaction.

B. Control Modules

Control modules are essential for the operation of adjustable resistors, particularly in digital applications.

1. **Digital Control Systems**: These systems utilize microcontrollers or digital signal processors to manage resistance adjustments. Users can input desired values through a user interface, and the control module adjusts the resistor accordingly.

2. **Analog Control Systems**: In contrast, analog control systems rely on physical adjustments, such as turning a knob. These systems are often simpler and more intuitive, making them suitable for applications where digital control is unnecessary.

C. Feedback Mechanisms

Feedback mechanisms are vital for ensuring accurate adjustments in chip adjustable resistors. These systems monitor the output and provide real-time data to the control module, allowing for precise tuning.

1. **Importance of Feedback**: Feedback ensures that the resistance value remains stable and accurate, even in the presence of external factors like temperature changes or component aging.

2. **Types of Feedback Systems**: Common feedback systems include closed-loop and open-loop configurations. Closed-loop systems continuously monitor output and adjust accordingly, while open-loop systems rely on preset values without real-time adjustments.

V. Applications of Chip Adjustable Resistors

A. Consumer Electronics

Chip adjustable resistors find extensive use in consumer electronics, where precision and adaptability are crucial.

1. **Audio Equipment**: In audio devices, adjustable resistors are used for volume control and tone adjustments, allowing users to customize their listening experience.

2. **Display Devices**: Adjustable resistors are employed in display technologies, such as LCDs and LEDs, to control brightness and color balance.

B. Industrial Applications

In industrial settings, chip adjustable resistors play a vital role in automation and measurement systems.

1. **Automation Systems**: These resistors are used in control circuits for machinery, enabling precise adjustments to operational parameters.

2. **Measurement Instruments**: Adjustable resistors are integral to calibration processes in measurement devices, ensuring accurate readings and reliable performance.

C. Automotive Applications

The automotive industry also benefits from chip adjustable resistors, particularly in advanced electronic systems.

1. **Engine Control Units**: Adjustable resistors are used in engine management systems to optimize performance and fuel efficiency.

2. **Infotainment Systems**: In modern vehicles, adjustable resistors are employed in audio and navigation systems, allowing for user-friendly control and customization.

VI. Advantages and Disadvantages

A. Advantages of Chip Adjustable Resistors

1. **Precision and Accuracy**: Chip adjustable resistors offer high precision, enabling fine-tuning of resistance values for optimal circuit performance.

2. **Space Efficiency**: Their compact design makes them ideal for modern electronics, where space is often at a premium.

B. Disadvantages

1. **Cost Considerations**: The complexity of chip adjustable resistors can lead to higher costs compared to fixed resistors, which may be a consideration for budget-sensitive projects.

2. **Complexity in Design**: Integrating adjustable resistors into circuits can introduce design challenges, particularly in ensuring stability and reliability.

VII. Future Trends and Innovations

A. Advances in Materials and Technology

The future of chip adjustable resistors is likely to see advancements in materials, leading to improved performance characteristics, such as enhanced temperature stability and reduced size.

B. Integration with Smart Technologies

As the Internet of Things (IoT) continues to grow, chip adjustable resistors will increasingly integrate with smart technologies, enabling remote control and automation in various applications.

C. Potential for Miniaturization

Ongoing efforts in miniaturization will likely result in even smaller chip adjustable resistors, making them suitable for a broader range of applications, including wearable technology and microelectronics.

VIII. Conclusion

Chip adjustable resistors are essential components in modern electronics, offering flexibility, precision, and adaptability. Understanding their components and modules provides valuable insights into their functionality and applications. As technology continues to evolve, chip adjustable resistors will play an increasingly important role in shaping the future of electronic design and innovation.

IX. References

A comprehensive list of academic journals, industry publications, and online resources can be provided to support further exploration of chip adjustable resistors and their applications in electronics.