Mainstream Capacitor Housing Product Series Parameters

I. Introduction

A. Definition of Capacitors

Capacitors are passive electronic components that store and release electrical energy in a circuit. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric field forms across the dielectric, allowing the capacitor to store energy. Capacitors are essential in various applications, from filtering and smoothing power supplies to timing circuits and energy storage systems.

B. Importance of Capacitor Housing

The housing of a capacitor plays a crucial role in its performance, reliability, and application suitability. It protects the internal components from environmental factors such as moisture, dust, and mechanical stress. Additionally, the housing influences thermal management, electrical characteristics, and overall lifespan. Therefore, understanding the parameters of capacitor housings is vital for engineers and designers when selecting the right component for their specific needs.

C. Overview of the Document's Purpose

This document aims to provide a comprehensive overview of mainstream capacitor housing product series parameters. It will explore the types of capacitor housings, key parameters, performance metrics, industry standards, applications, and emerging trends. By the end of this article, readers will have a clearer understanding of how to choose the right capacitor housing for their applications.

II. Types of Capacitor Housings

A. Overview of Common Capacitor Types

Capacitors come in various types, each with unique characteristics and applications. The most common types include:

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications. They are typically housed in a ceramic casing, providing excellent dielectric properties.

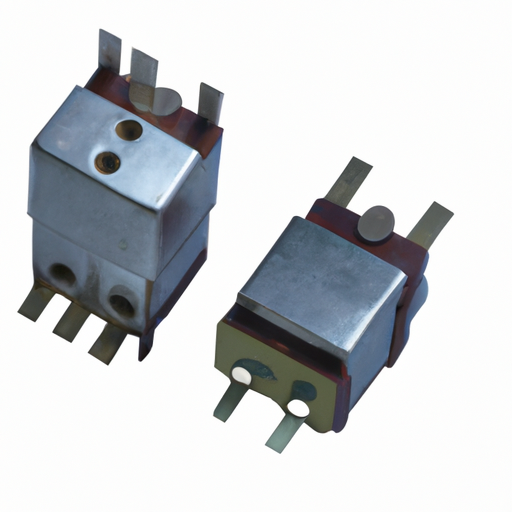

2. **Electrolytic Capacitors**: These capacitors are polarized and offer high capacitance values in a relatively small size. They are commonly used in power supply circuits and are housed in aluminum or tantalum casings.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their reliability and low loss. They are often used in audio and power applications and can be housed in plastic or metal enclosures.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance and stability. They are often used in compact electronic devices and are typically housed in a hermetically sealed metal case.

B. Housing Materials

The choice of housing material significantly impacts the performance and durability of capacitors. Common materials include:

1. **Plastic**: Lightweight and cost-effective, plastic housings are commonly used for ceramic and film capacitors. They provide good insulation and moisture resistance.

2. **Metal**: Metal housings, often used for electrolytic and tantalum capacitors, offer excellent protection against environmental factors and mechanical stress. They also provide better thermal conductivity.

3. **Ceramic**: Ceramic housings are typically used for high-frequency applications due to their excellent dielectric properties. They are also resistant to high temperatures.

4. **Composite Materials**: These materials combine the benefits of different substances, offering enhanced performance characteristics such as improved thermal management and mechanical strength.

III. Key Parameters of Capacitor Housings

A. Physical Dimensions

1. **Size and Shape**: The physical dimensions of a capacitor housing are critical for fitting into specific applications. Capacitors come in various shapes, including cylindrical, rectangular, and surface-mount designs.

2. **Mounting Options**: Capacitor housings can be designed for different mounting methods, such as through-hole, surface mount, or snap-in. The choice of mounting affects the ease of installation and the overall design of the electronic device.

B. Electrical Characteristics

1. **Voltage Rating**: The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is essential to select a capacitor with a voltage rating higher than the maximum voltage in the application.

2. **Capacitance Value**: This parameter defines the amount of electrical charge a capacitor can store. It is measured in farads (F) and is crucial for determining the capacitor's suitability for specific applications.

3. **Tolerance Levels**: Tolerance indicates the allowable variation in capacitance value. Capacitors with tighter tolerances are often required in precision applications.

C. Thermal Properties

1. **Operating Temperature Range**: Capacitors must operate within specific temperature ranges to ensure reliability. The housing material and design influence the capacitor's ability to withstand temperature fluctuations.

2. **Thermal Conductivity**: Good thermal conductivity in the housing material helps dissipate heat generated during operation, enhancing the capacitor's lifespan and performance.

D. Environmental Resistance

1. **Moisture Resistance**: Capacitor housings must protect against moisture ingress, which can lead to failure. This is particularly important in outdoor or humid environments.

2. **Chemical Resistance**: Capacitors may be exposed to various chemicals in industrial applications. The housing material should resist corrosion and degradation from these substances.

3. **UV Resistance**: For applications exposed to sunlight, UV resistance is crucial to prevent degradation of the housing material over time.

IV. Performance Metrics

A. Reliability and Lifespan

1. **Failure Rates**: Understanding the failure rates of different capacitor types and housings is essential for predicting their reliability in applications.

2. **Aging Effects**: Capacitors can experience aging effects that impact their performance over time. The housing material and design can influence how well a capacitor withstands these effects.

B. Efficiency Ratings

1. **ESR (Equivalent Series Resistance)**: ESR is a critical parameter that affects the efficiency of capacitors, particularly in power applications. Lower ESR values indicate better performance.

2. **ESL (Equivalent Series Inductance)**: ESL affects the frequency response of capacitors. Understanding ESL is essential for applications requiring high-frequency performance.

C. Frequency Response

1. **Impedance Characteristics**: The impedance of a capacitor varies with frequency. Understanding these characteristics is crucial for applications in RF and audio circuits.

2. **Self-Resonant Frequency**: This is the frequency at which a capacitor's reactance becomes zero. It is an important parameter for high-frequency applications.

V. Industry Standards and Certifications

A. Overview of Relevant Standards

1. **IEC (International Electrotechnical Commission)**: The IEC sets international standards for electrical and electronic components, including capacitors.

2. **UL (Underwriters Laboratories)**: UL certification ensures that capacitors meet safety and performance standards, providing assurance to manufacturers and consumers.

3. **RoHS (Restriction of Hazardous Substances)**: RoHS compliance ensures that capacitors are free from hazardous materials, promoting environmental sustainability.

B. Importance of Compliance

1. **Safety Considerations**: Compliance with industry standards ensures that capacitors are safe to use in various applications, reducing the risk of failure.

2. **Market Acceptance**: Products that meet recognized standards are more likely to gain acceptance in the market, enhancing their competitiveness.

VI. Applications of Capacitor Housings

A. Consumer Electronics

Capacitors are widely used in consumer electronics, including smartphones, televisions, and audio equipment. The choice of housing material and design is crucial for ensuring performance and reliability.

B. Automotive Industry

In the automotive sector, capacitors are used in various applications, from power management systems to infotainment units. The housings must withstand harsh environmental conditions and vibrations.

C. Industrial Equipment

Capacitors play a vital role in industrial equipment, including motors and power supplies. The housing must provide protection against dust, moisture, and chemicals.

D. Renewable Energy Systems

With the rise of renewable energy systems, capacitors are increasingly used in solar inverters and wind turbines. The housing must be designed to withstand outdoor conditions and ensure long-term reliability.

VII. Trends and Innovations in Capacitor Housing

A. Miniaturization and Compact Designs

As electronic devices become smaller and more compact, there is a growing demand for miniaturized capacitors. Innovations in housing design and materials are enabling the production of smaller, more efficient capacitors.

B. Advanced Materials and Coatings

The development of advanced materials and coatings is enhancing the performance and durability of capacitor housings. These innovations improve thermal management, moisture resistance, and overall reliability.

C. Smart Capacitors and IoT Integration

The integration of smart technology into capacitors is an emerging trend. Smart capacitors can monitor their performance and communicate with other devices, enabling more efficient energy management in IoT applications.

VIII. Conclusion

A. Summary of Key Points

In summary, the housing of capacitors is a critical factor that influences their performance, reliability, and suitability for various applications. Understanding the types of housings, key parameters, performance metrics, and industry standards is essential for selecting the right capacitor for specific needs.

B. Future Outlook for Capacitor Housing Products

As technology continues to evolve, the demand for advanced capacitor housing solutions will grow. Innovations in materials, design, and smart technology will shape the future of capacitor products.

C. Importance of Choosing the Right Capacitor Housing for Applications

Choosing the right capacitor housing is vital for ensuring optimal performance and reliability in electronic devices. By considering the parameters discussed in this document, engineers and designers can make informed decisions that enhance the functionality and longevity of their products.

IX. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Capacitor Market Analysis Report

- Trends in Capacitor Technology

C. Manufacturer Specifications

- Manufacturer datasheets for various capacitor types

- Technical specifications from leading capacitor manufacturers

This comprehensive overview of mainstream capacitor housing product series parameters provides valuable insights for engineers, designers, and anyone interested in understanding the critical aspects of capacitor housings in electronic applications.