The Production Process of Mainstream Inductors

I. Introduction

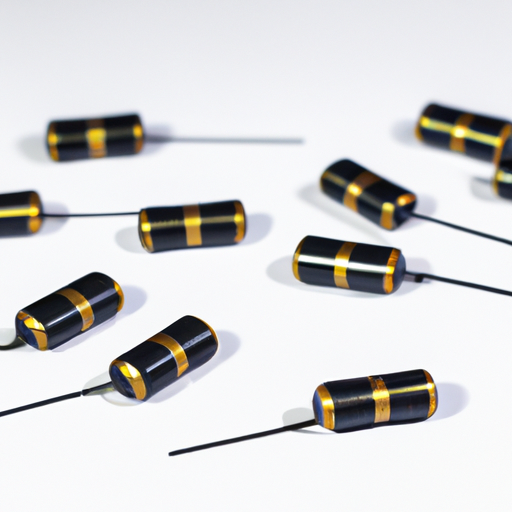

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, including power supplies, filters, and oscillators. As the demand for electronic devices continues to grow, understanding the production process of inductors becomes increasingly important. This blog post will explore the various stages involved in the manufacturing of mainstream inductors, from raw materials to future trends in production.

II. Types of Inductors

Inductors come in several types, each designed for specific applications.

A. Air-core Inductors

Air-core inductors do not use a magnetic core, relying instead on the air surrounding the coil to create inductance. They are typically used in high-frequency applications due to their low losses.

B. Iron-core Inductors

Iron-core inductors utilize an iron core to enhance inductance. The core material increases the magnetic field strength, making these inductors suitable for low-frequency applications.

C. Ferrite-core Inductors

Ferrite-core inductors use ferrite materials, which are ceramic compounds made of iron oxide mixed with other metals. These inductors are popular in high-frequency applications due to their high magnetic permeability and low losses.

D. Other Specialized Inductors

There are also specialized inductors, such as toroidal inductors, which are shaped like a doughnut, and variable inductors, which allow for adjustable inductance. Each type serves unique purposes in electronic circuits.

III. Raw Materials

The production of inductors begins with the selection of raw materials, which are critical to the performance and reliability of the final product.

A. Conductive Materials

1. **Copper Wire**: Copper is the most commonly used conductive material due to its excellent electrical conductivity and malleability. It is often used for winding the coils of inductors.

2. **Aluminum Wire**: Aluminum is a lighter and less expensive alternative to copper, though it has lower conductivity. It is sometimes used in applications where weight is a concern.

B. Core Materials

1. **Ferrite**: Ferrite is a popular core material for high-frequency inductors due to its high magnetic permeability and low eddy current losses.

2. **Iron**: Iron cores are used in low-frequency inductors, providing a strong magnetic field but with higher losses at higher frequencies.

3. **Laminated Steel**: Laminated steel cores are used to reduce eddy current losses in transformers and inductors, making them suitable for various applications.

C. Insulating Materials

1. **Enamel Coatings**: Enamel coatings are applied to copper wire to prevent short circuits between turns of the coil.

2. **Plastic and Resin Materials**: These materials are used for insulation and encapsulation, providing protection against environmental factors.

IV. Design and Engineering

The design and engineering phase is crucial for ensuring that the inductor meets specific performance requirements.

A. Specifications and Requirements

Engineers define the specifications for the inductor, including inductance value, current rating, and physical dimensions, based on the intended application.

B. Simulation and Modeling

Advanced software tools are used to simulate the inductor's performance under various conditions. This modeling helps identify potential issues before physical prototypes are created.

C. Prototyping

Once the design is finalized, prototypes are built to test the inductor's performance. This phase allows for adjustments and refinements before mass production.

V. Manufacturing Process

The manufacturing process of inductors involves several key steps.

A. Wire Winding

1. **Manual vs. Automated Winding**: Inductor coils can be wound manually or using automated machines. Automated winding is more efficient and ensures consistency in the winding process.

2. **Winding Techniques**: Various techniques, such as layer winding and bifilar winding, are employed to achieve the desired inductance and minimize parasitic effects.

B. Core Assembly

1. **Insertion of Core Materials**: After winding, the core material is inserted into the coil. The type of core used will depend on the inductor's design specifications.

2. **Types of Core Assembly**: Core assembly can involve different methods, such as pressing or gluing, to secure the core in place.

C. Insulation Application

1. **Coating Processes**: Insulation is applied to prevent electrical shorts and protect the inductor from environmental factors. This can involve dipping, spraying, or using adhesive films.

2. **Drying and Curing**: After insulation application, the inductors undergo drying and curing processes to ensure the insulation adheres properly and provides adequate protection.

D. Soldering and Terminal Attachment

1. **Methods of Attachment**: Terminals are attached to the inductor using soldering techniques, ensuring a reliable electrical connection.

2. **Quality Control Measures**: Quality control checks are performed to ensure that the solder joints are strong and that the inductors meet specified standards.

VI. Testing and Quality Assurance

Testing is a critical step in the production process to ensure that inductors perform as expected.

A. Electrical Testing

1. **Inductance Measurement**: Inductors are tested for their inductance values using specialized equipment to ensure they meet design specifications.

2. **Resistance and Q-factor Testing**: The resistance and quality factor (Q-factor) are measured to assess the inductor's efficiency and performance.

B. Mechanical Testing

1. **Durability and Stress Tests**: Inductors undergo mechanical testing to evaluate their durability under various stress conditions, including vibration and temperature changes.

2. **Environmental Testing**: Environmental tests assess the inductor's performance in different conditions, such as humidity and temperature extremes.

C. Compliance with Industry Standards

Inductors must comply with industry standards, such as those set by the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), to ensure safety and reliability.

VII. Packaging and Distribution

Once the inductors pass testing, they are prepared for packaging and distribution.

A. Packaging Methods

Inductors are packaged in protective materials to prevent damage during transportation. Packaging may include anti-static bags, boxes, or trays.

B. Inventory Management

Effective inventory management ensures that inductors are readily available for distribution while minimizing excess stock.

C. Distribution Channels

Inductors are distributed through various channels, including direct sales to manufacturers, electronic component distributors, and online platforms.

VIII. Challenges in Inductor Production

The production of inductors faces several challenges that manufacturers must navigate.

A. Material Sourcing and Cost Fluctuations

The availability and cost of raw materials can fluctuate, impacting production costs and timelines. Manufacturers must establish reliable supply chains to mitigate these risks.

B. Technological Advancements

As technology evolves, manufacturers must keep pace with advancements in materials and production techniques to remain competitive.

C. Environmental Considerations

Sustainability is becoming increasingly important in manufacturing. Companies are exploring eco-friendly materials and processes to reduce their environmental impact.

IX. Future Trends in Inductor Manufacturing

The future of inductor manufacturing is likely to be shaped by several trends.

A. Innovations in Materials

Research into new materials, such as nanomaterials and composites, may lead to the development of more efficient and compact inductors.

B. Miniaturization and Integration

As electronic devices become smaller, the demand for miniaturized inductors that can be integrated into compact circuits will grow.

C. Sustainable Manufacturing Practices

Manufacturers are likely to adopt more sustainable practices, including recycling materials and reducing waste, to meet consumer demand for environmentally friendly products.

X. Conclusion

In conclusion, the production process of mainstream inductors is a complex and multifaceted endeavor that involves careful consideration of materials, design, manufacturing techniques, and quality assurance. As inductors continue to play a vital role in modern electronics, understanding their production process is essential for engineers, manufacturers, and consumers alike. The future of inductor manufacturing looks promising, with innovations in materials and sustainable practices paving the way for more efficient and environmentally friendly products. As technology advances, the importance of inductors in electronic circuits will only continue to grow, making their production process a critical area of focus in the electronics industry.